MT25QU512ABB1EW9-0SIT Common troubleshooting and solutions

Introduction to MT25QU512ABB1EW9-0SIT and Common Troubleshooting Issues

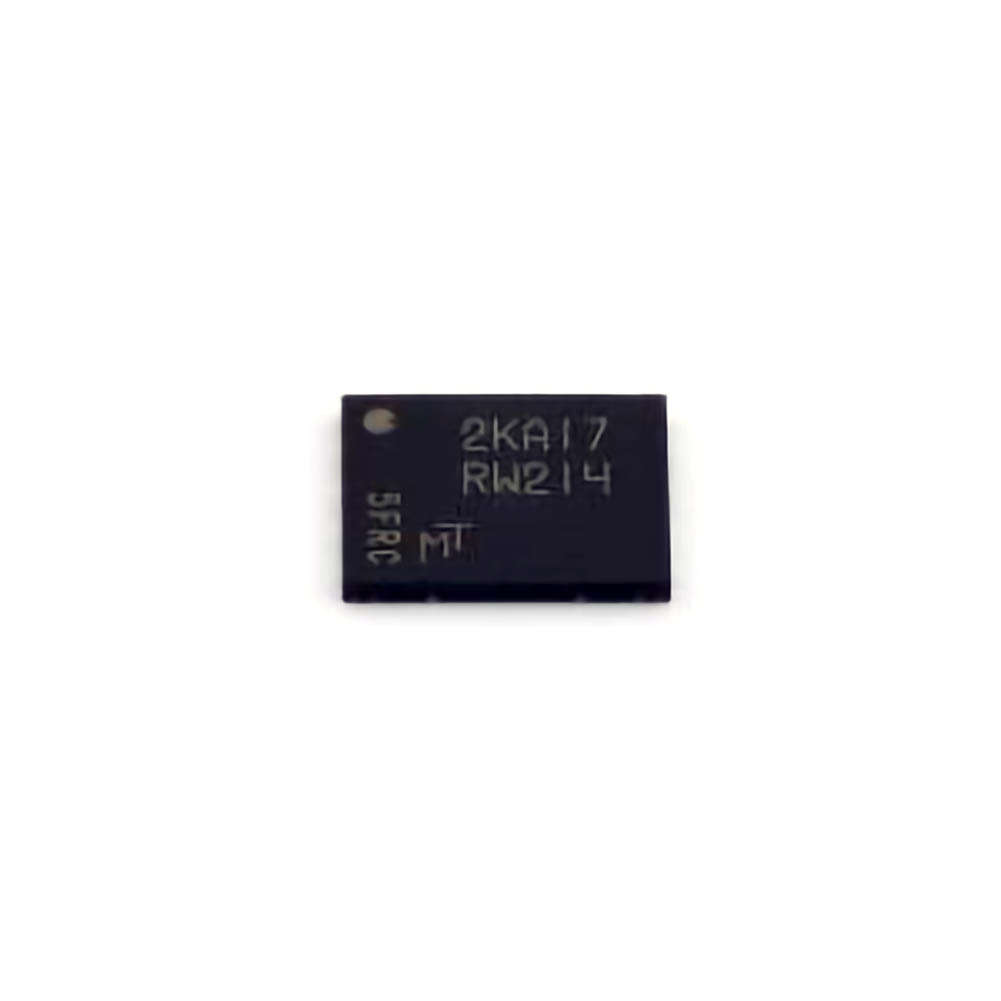

The MT25QU512ABB1EW9-0SIT is a 512Mb (64MB) quad SPI (Serial Peripheral Interface) NOR flash memory chip developed by Micron. This memory device is commonly used in embedded systems, consumer electronics, and various industrial applications. Offering high-speed data read/write operations and low Power consumption, it’s a highly reliable solution for storage in many electronic devices.

However, as with any component, there can be occasional issues related to its functionality, which can disrupt the operation of the entire system. Identifying and resolving these issues can sometimes be challenging, especially for engineers and technicians working on complex embedded systems. This article will guide you through common problems faced with the MT25QU512ABB1EW9-0SIT, provide insight into their causes, and offer troubleshooting solutions to keep your project on track.

1.1 Power and Connection Issues

One of the most common issues faced when using the MT25QU512ABB1EW9-0SIT flash memory is related to power and connectivity. If the flash memory is not properly powered or if there is an issue with the connections, the system will fail to recognize the device or may behave erratically.

Symptoms:

The system does not detect the memory chip at startup.

Read/write operations are very slow or fail intermittently.

The device intermittently goes into an unresponsive state.

Troubleshooting Steps:

Verify Power Supply: Ensure that the device is receiving the correct voltage. The MT25QU512ABB1EW9-0SIT operates at 2.3V to 3.6V, so check that your power supply provides this voltage range consistently. A fluctuation in the supply voltage can lead to erratic behavior.

Check for Grounding Issues: Ensure proper grounding and avoid any floating pins on the board that may lead to signal noise or poor performance. A poor ground connection could cause instability in the device.

Inspect Connections and Soldering: Poor soldering or broken traces on the PCB can prevent the flash memory from establishing a proper connection. Examine the physical connections between the memory chip and the host controller, particularly for any cold solder joints or cracked connections.

Check SPI Signals: Ensure that the SPI signals (MOSI, MISO, SCK, and CS) are functioning correctly and that they adhere to the proper voltage levels specified in the datasheet.

1.2 Incorrect Read/Write Operations

Another issue developers may encounter is the failure of read or write operations. The MT25QU512ABB1EW9-0SIT is designed for high-speed operations, but there are several factors that could interfere with its normal behavior, such as Timing mismatches, improper initialization, or signal integrity problems.

Symptoms:

Data corruption occurs when reading or writing.

The flash memory is not responding to commands.

Slow data transfer rates despite proper configuration.

Troubleshooting Steps:

Timing Adjustments: Ensure that your SPI Clock frequency is within the acceptable limits for the MT25QU512ABB1EW9-0SIT. Operating the flash memory at a frequency that exceeds its rated capability can result in unreliable performance. Typically, the maximum clock frequency is 133 MHz, but this could vary depending on environmental conditions or other parameters.

Review Command Sequences: The MT25QU512ABB1EW9-0SIT uses specific command sequences for reading, writing, and erasing. Verify that your firmware correctly implements these sequences. Refer to the device datasheet to ensure the correct flow of operations.

Check Write Protection: Some operations may fail due to write protection mechanisms. Ensure that the write protection (WP) pin is not engaged, or check if the device is in the read-only mode.

Signal Integrity: Noise or interference on the SPI bus can affect the integrity of the data being transferred. Ensure that the signal lines are clean and not subject to electromagnetic interference ( EMI ) from surrounding components.

1.3 Erase and Sector Issues

When working with flash memory, erasing and reprogramming the memory can sometimes lead to complications, especially if sectors are not correctly erased or if there are underlying issues with the wear leveling process.

Symptoms:

Unable to erase or overwrite specific memory sectors.

Flash memory is stuck in a “programming” state after erasing.

Read operations return unexpected data values.

Troubleshooting Steps:

Check Erase Mechanism: The MT25QU512ABB1EW9-0SIT uses a block-erase function. Ensure that your erase command targets the correct block. Incorrect block targeting may result in unexpected behavior or failure to erase.

Wear Leveling Considerations: Like all flash memory, the MT25QU512ABB1EW9-0SIT has a limited number of program/erase cycles. If you repeatedly erase and write to the same sector, you might hit the wear-leveling threshold, leading to failure. In such cases, consider implementing wear-leveling algorithms in the firmware to distribute the write cycles more evenly.

Sector Locking: The device supports the option of locking specific sectors for security reasons. Make sure the sectors you intend to write to are not locked or protected. Check the status of the sector lock bit and clear it if necessary.

Temperature Sensitivity: Flash memory devices, including the MT25QU512ABB1EW9-0SIT, can be sensitive to high or low temperatures. Excessive temperature fluctuations during erasing or programming can result in incomplete operations or data corruption.

1.4 Inconsistent Data Readouts

Sometimes, the system might read incorrect data from the MT25QU512ABB1EW9-0SIT, even though the write operations were completed successfully. This can be due to timing issues, incorrect configuration, or physical issues with the flash memory.

Symptoms:

The read data does not match the written data.

Data retrieval is incomplete or corrupted.

Troubleshooting Steps:

SPI Clock and Timing Checks: Inconsistent data can be caused by timing mismatches between the host controller and the flash memory. Review the SPI clock and ensure the data setup and hold times are within the specified limits.

Check for Bus Contention: If there are other devices on the same SPI bus, ensure that there is no contention. Only one device should be active on the bus at a time to avoid conflicts.

Review Initialization Code: Sometimes, data read failures can be traced back to improper initialization. Ensure that the correct initialization sequence is followed, including setting up the SPI bus, selecting the right mode, and configuring the necessary parameters for the memory chip.

1.5 Data Retention Issues

Flash memory devices like the MT25QU512ABB1EW9-0SIT rely on charge retention to store data. Over time, if the memory chip is exposed to high temperatures or if the device is powered down for extended periods, data retention can degrade, leading to the loss of previously stored data.

Symptoms:

Data loss after powering down the system.

Corrupted data after extended periods of use.

Troubleshooting Steps:

Monitor Storage Environment: The MT25QU512ABB1EW9-0SIT has a typical data retention time of 20 years at 25°C, but extreme temperatures can reduce this significantly. Ensure that the environment around the flash memory is within the recommended operational range.

Use Low Power Modes: If you are storing critical data and expect the system to remain off for an extended period, make use of low power or deep sleep modes to minimize the chance of data degradation.

Advanced Troubleshooting and Preventive Measures

As you advance in your usage of the MT25QU512ABB1EW9-0SIT, you might encounter more complex issues. Here, we’ll delve deeper into advanced troubleshooting techniques, covering potential long-term solutions and preventive measures to avoid common pitfalls.

2.1 Advanced Debugging with Error Detection and Logging

To facilitate effective troubleshooting, it is essential to implement error detection mechanisms within your firmware. This can help pinpoint the source of a problem and reduce debugging time.

Symptoms:

Unpredictable behavior that cannot be easily reproduced.

Hard-to-diagnose failures during read/write operations.

Troubleshooting Steps:

Implement ECC (Error-Correcting Code): Many advanced flash memory chips, including the MT25QU512ABB1EW9-0SIT, support ECC, which can help detect and correct small data errors. If your system does not already use ECC, consider adding it to your design to improve the reliability of data reads and writes.

Use Debugging Tools: Hardware debugging tools like logic analyzers or oscilloscopes can be invaluable for diagnosing timing and signal integrity problems. Use these tools to capture the SPI bus traffic and verify that the read/write commands are being executed correctly.

Introduce Watchdog Timers: A watchdog timer can be used to reset the system in case of an error or unexpected behavior. This can prevent the system from becoming unresponsive in the event of an issue with the memory chip.

2.2 Firmware Updates and Compatibility Issues

As memory chip technology advances, new firmware versions or updates may offer performance improvements or bug fixes. It's essential to keep your firmware up to date to ensure compatibility with the latest versions of the MT25QU512ABB1EW9-0SIT.

Symptoms:

Incompatibility with newer versions of the MT25QU512ABB1EW9-0SIT.

Unexpected behavior after a firmware update.

Troubleshooting Steps:

Stay Up-to-Date with Manufacturer Guidelines: Regularly check for updates from Micron, as they may release new firmware or updates that resolve known issues. Always consult the latest datasheet to ensure you are using the correct initialization, configuration, and command sequences.

Backward Compatibility: If you are upgrading from an older version of the device, ensure backward compatibility in your firmware. Some changes in the device’s command set or timing specifications could cause previously working code to fail.

Test Extensively After Firmware Changes: After updating firmware or making changes to the system’s memory handling code, thoroughly test the memory chip’s read, write, and erase operations to ensure everything functions as expected.

2.3 Preventive Measures for Long-Term Reliability

Preventive measures are crucial for ensuring that the MT25QU512ABB1EW9-0SIT performs reliably over its lifetime. While some factors are beyond your control, such as temperature variations, others can be mitigated through design choices.

Symptoms:

Long-term reliability issues leading to data corruption or failure.

Early wear-out of the flash memory.

Preventive Measures:

Thermal Management : Implement appropriate thermal management strategies, such as heat sinks, passive cooling, or proper airflow around the memory chip. Excessive temperatures can accelerate wear and reduce the retention time of stored data.

Optimize Write Cycles: Avoid excessive write/erase cycles on individual blocks. Implement wear leveling and other techniques to ensure that writes are distributed evenly across the memory.

Implement Power Fail Detection: In applications where power loss could lead to data corruption, consider adding a power fail detection mechanism to gracefully handle power-down events. This can help ensure that data is properly written and that the system doesn't become corrupted after unexpected power losses.

By following these troubleshooting steps and preventive measures, engineers can ensure the MT25QU512ABB1EW9-0SIT operates reliably and efficiently throughout its lifetime. Whether it’s resolving simple power issues or tackling more advanced memory management concerns, these strategies can significantly improve your experience with Micron’s flash memory technology.

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.

Partnering with an electronic components supplier sets your team up for success, ensuring the design, production, and procurement processes are quality and error-free.