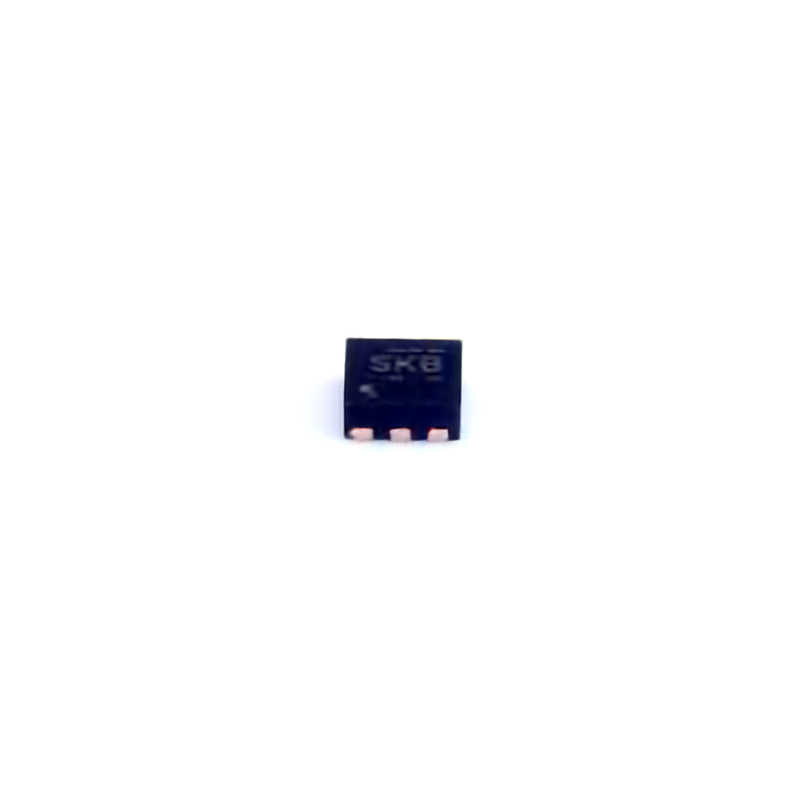

TPS25200DRVR Common troubleshooting and solutions

Understanding the TPS25200DRVR and Common Issues

The TPS25200DRVR is a Power distribution switch from Texas Instruments designed to provide robust protection and control in systems that require power distribution. It’s widely used in USB power delivery applications, portable electronics, automotive systems, and other embedded devices. Its key features include overcurrent protection, thermal shutdown, and fault reporting, making it an excellent choice for preventing damage to sensitive components.

Despite its robust design, users occasionally face issues that could hinder performance or cause malfunction in their systems. In this section, we’ll explore the most common problems users encounter with the TPS25200DRVR, such as power delivery failures, thermal issues, and voltage drops.

1. Power Delivery Failure

One of the most common issues when using the TPS25200DRVR is a failure in power delivery. This can manifest as the connected device not receiving the proper voltage or current, leading to power failure or the device failing to start.

Possible Causes:

Incorrect Input Voltage: Ensure that the input voltage is within the recommended range for the device (4.5V to 5.5V). A supply voltage that’s too high or too low can cause the device to stop functioning properly.

Overcurrent Protection Triggered: The TPS25200DRVR includes an overcurrent protection feature. If the connected load draws more current than the threshold (typically set to 2.5A or 3.0A depending on the configuration), the device will enter a fault condition and stop delivering power.

Solutions:

Double-check the input voltage level and ensure it is stable.

Measure the current draw from the connected device and verify it is within the allowable range. If necessary, reduce the load or adjust the current limiting settings.

Check for any short circuits in the power distribution path that could be triggering overcurrent protection.

2. Thermal Shutdown

Thermal shutdown is another frequent issue, especially in high-power applications where excessive heat can accumulate. If the TPS25200DRVR detects that the junction temperature exceeds the threshold (typically 150°C), it will automatically shut down to prevent thermal damage.

Possible Causes:

Excessive Power Dissipation: High current loads or inadequate cooling can cause the device to dissipate too much power, leading to overheating.

Insufficient PCB Thermal Design: Poor thermal management in the PCB layout can hinder the heat dissipation, causing the IC to reach thermal limits more quickly.

Solutions:

Add or improve heat sinks or cooling solutions to your design.

Check the PCB layout for proper thermal vias and copper area to dissipate heat.

Use the device in environments with better airflow or lower ambient temperatures to keep the junction temperature within safe limits.

3. Voltage Drop

Another issue that may arise with the TPS25200DRVR is a significant voltage drop across the power switch, especially under load. This could result in the connected device receiving lower-than-expected voltage, potentially leading to instability or malfunction.

Possible Causes:

High Rds(on): The on-state resistance of the MOSFET within the TPS25200DRVR may increase with temperature or excessive current, leading to a higher voltage drop.

Undersized PCB Traces: If the PCB traces are not sized properly to handle the current, this can cause excessive resistance in the path, leading to a voltage drop.

Solutions:

Minimize the current draw through the power distribution switch or use a higher-rated device if the application requires higher current.

Ensure that the PCB traces are thick enough and have low resistance to reduce the voltage drop.

4. Fault Detection and Reporting Issues

Fault detection is a key feature of the TPS25200DRVR, allowing the device to notify the system when there’s an overcurrent, overvoltage, or thermal event. However, the reporting mechanism can sometimes be confusing or not work as expected.

Possible Causes:

Improper Fault Pin Configuration: The fault detection output pin may be improperly configured or not connected in a way that ensures accurate fault reporting.

Fault Conditions Not Properly Resolved: Sometimes the system doesn’t clear a fault condition even after the issue is resolved. This could happen due to issues with the fault reset mechanism.

Solutions:

Review the fault pin connection and ensure it's wired to a monitoring system (such as a microcontroller) to capture and respond to faults.

After a fault condition, make sure to reset the system appropriately by toggling the enable pin or clearing the fault latch.

Advanced Troubleshooting Tips and Design Considerations

While common issues like power delivery failure and thermal shutdown can usually be resolved with basic checks, advanced troubleshooting is sometimes necessary to identify more subtle problems with the TPS25200DRVR. In this section, we’ll dive deeper into advanced diagnostics and provide additional design considerations to improve the reliability of your power distribution system.

1. Verifying and Adjusting Overcurrent Protection

The TPS25200DRVR includes an adjustable overcurrent protection feature, which allows the user to set the current limit based on the requirements of the application. However, users may experience issues when this limit is set too high or too low.

Possible Causes:

Incorrect Current Limit Settings: If the current limit is set too low, the device may shut down unnecessarily. On the other hand, a very high current limit might not provide sufficient protection to the load.

Transient Current Spikes: Some devices experience brief current spikes during startup, which could cause the TPS25200DRVR to enter fault condition even if the sustained current draw is within the limit.

Solutions:

Fine-tune the current limit to ensure it provides adequate protection without causing unnecessary shutdowns.

Use an external capacitor or inductor to smooth out current spikes and reduce the likelihood of triggering overcurrent protection during power-up.

2. Managing Inrush Current

Inrush current is a common issue in systems with capacitive loads, such as those with large input Capacitors or battery charging circuits. During power-up, the initial surge of current can be significantly higher than the normal operating current, potentially triggering overcurrent protection in the TPS25200DRVR.

Possible Causes:

Large Input Capacitors: Systems with large decoupling capacitors may generate inrush currents that exceed the current limit.

Capacitive Load: Some loads, especially those involving motors or large power supplies, may present a large initial current draw.

Solutions:

Use an NTC thermistor or a soft-start circuit to limit inrush current at power-up.

Increase the current limit setting slightly, but within safe operational limits, to allow for a higher inrush current.

3. Enhancing Fault Handling with External Components

Although the TPS25200DRVR has built-in fault detection, users can further enhance its fault-handling capabilities by adding external components.

Possible Solutions:

External Fault Indicator: Add an external fault indicator LED or a status signal to help users quickly diagnose the state of the system.

Fault Reset Circuit: Implement a dedicated reset circuit that clears latched faults when necessary, ensuring the system is ready for normal operation after a fault condition.

4. Improving PCB Layout for Better Performance

The layout of the PCB is critical to the performance of the TPS25200DRVR. Improper layout can lead to increased resistance, excessive heat buildup, or unstable performance.

Solutions:

Ensure that the high-current paths are kept short and have low resistance by using wider PCB traces or thicker copper layers.

Keep the thermal vias and heat dissipation paths clear of any components to allow efficient heat removal.

Use proper grounding techniques to minimize noise and ensure stable operation of the device.

5. Using Thermal Simulation Tools

For more advanced designs, it’s a good idea to use thermal simulation tools to predict how the TPS25200DRVR will behave under different thermal conditions. These tools can help you optimize your PCB layout for heat dissipation and ensure that the IC stays within safe operating temperatures.

Conclusion

The TPS25200DRVR is a powerful and reliable power distribution switch that can protect your devices from a range of issues such as overcurrent, thermal shutdown, and voltage drops. However, like any electronic component, it’s essential to understand how to troubleshoot and optimize your design to avoid common issues. By carefully considering the voltage levels, current limits, thermal management, and fault detection systems, you can ensure smooth and efficient operation in your applications. Proper design and testing will ultimately help you maximize the lifespan and performance of the TPS25200DRVR, making it an indispensable component in your system.

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.

Partnering with an electronic components supplier sets your team up for success, ensuring the design, production, and procurement processes are quality and error-free.