AMC1311DWVR Common troubleshooting and solutions

Introduction and Common Issues with AMC1311DWVR

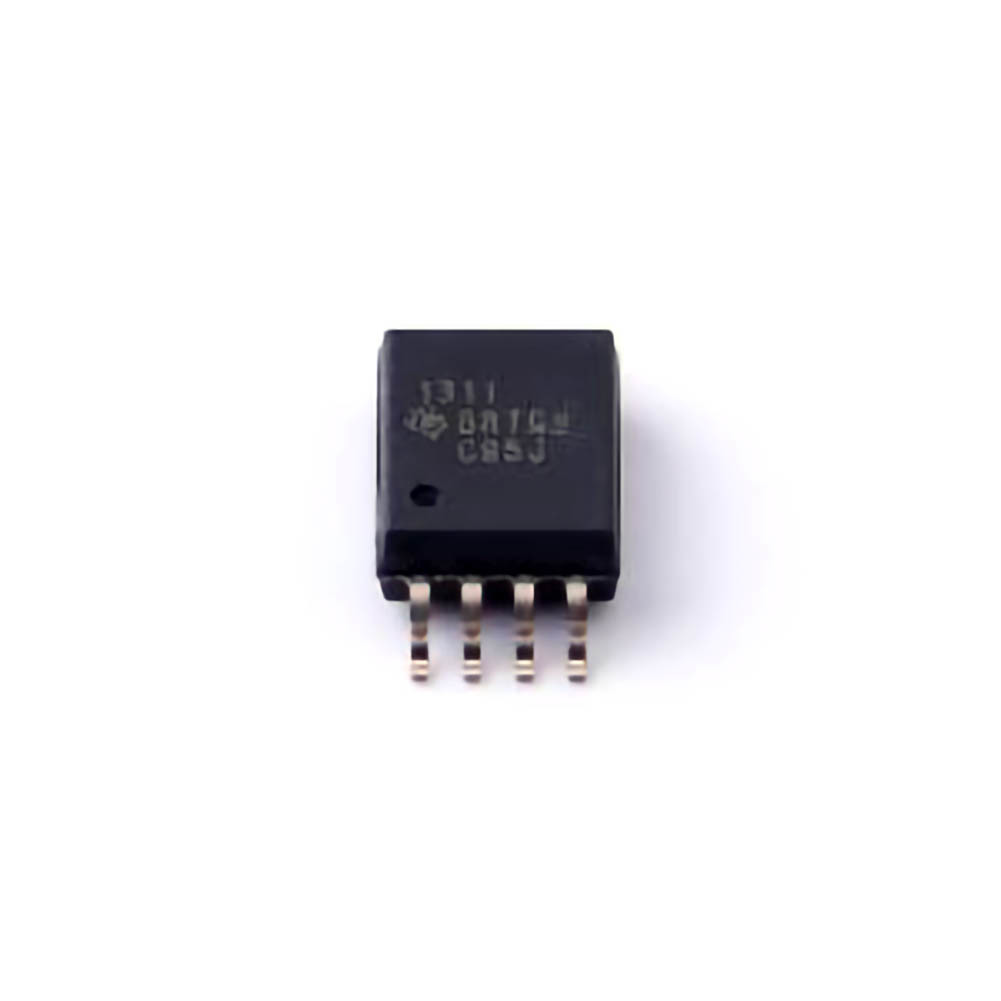

The AMC1311DWVR, a precision digital isolator, plays a critical role in applications that require the separation of high-voltage and low-voltage systems, particularly in industrial and automotive settings. Known for its superior isolation and noise immunity, the AMC1311DWVR is designed to protect sensitive circuits from electrical noise, spikes, and transients.

However, even the most reliable components can present challenges during installation or operation. This article explores some of the most common issues users face when working with the AMC1311DWVR and offers practical troubleshooting solutions.

1. Power Supply Issues

One of the most common problems that can arise when using the AMC1311DWVR is related to the power supply. As a precision isolator, the AMC1311 requires a stable and adequate power supply to function correctly. Power supply problems can manifest in various ways, such as malfunctioning isolation or erratic behavior.

Possible Causes:

Insufficient voltage: The AMC1311DWVR typically requires a 3.3V or 5V supply, depending on the system's needs. Any fluctuation below the required voltage can cause instability in the isolation performance.

Noise or ripple in the power supply: High-frequency noise or ripple on the power supply can affect the isolator’s operation, leading to errors or degraded performance.

Solution:

Verify the power supply voltage: Use a multimeter or oscilloscope to ensure that the supply voltage is within the recommended range (typically 3.3V or 5V). If the voltage is lower than expected, check the power supply or replace it with a more reliable one.

Filter power supply noise: Adding decoupling capacitor s (e.g., 0.1µF ceramic capacitors) close to the AMC1311DWVR power pins can help filter out high-frequency noise or ripple. A low-pass filter on the supply line might also be helpful for filtering higher-frequency noise.

2. Signal Integrity Problems

Signal integrity issues are a common concern in many high-speed digital applications, including those using the AMC1311DWVR. The performance of the digital isolator can be compromised if the signals are not properly managed.

Possible Causes:

Improper signal routing: Long traces, poor PCB layout, or inadequate grounding can result in signal reflections, crosstalk, or noise coupling, which can degrade performance.

High-frequency noise: As a high-speed digital isolator, the AMC1311DWVR requires careful attention to signal integrity. Excessive noise from nearby high-power circuits or electromagnetic interference ( EMI ) can disrupt communication between the isolator and the surrounding components.

Solution:

Optimize PCB layout: Ensure that the traces carrying signals to and from the AMC1311DWVR are as short and direct as possible. Keep these traces away from high-voltage or noisy areas on the PCB.

Use differential signaling: The AMC1311DWVR supports differential signal input and output. Ensure that the differential signals (such as LVDS) are routed correctly with proper termination resistors to maintain signal integrity.

Shield and ground: Use proper grounding techniques and consider adding shielding to reduce EMI. Ground planes and careful routing of high-speed signals can significantly improve performance and reduce noise interference.

3. Incorrect Pin Configuration

A common mistake during the setup of the AMC1311DWVR is an incorrect pin configuration. The device features several control pins that allow for specific functionalities such as enabling the isolation, configuring logic levels, and setting up default states.

Possible Causes:

Misconnection of pins: If any of the control or configuration pins are incorrectly connected, the device may not perform as expected, leading to faults or erratic behavior.

Unused pins: Some of the control pins on the AMC1311DWVR might not be used in certain applications. Leaving them floating or improperly terminated can cause unpredictable results.

Solution:

Double-check the datasheet: Always refer to the datasheet to ensure the proper connection of each pin. Pay close attention to the pinout diagram to make sure each pin is connected correctly according to the desired functionality.

Properly terminate unused pins: If some control pins are not used, they should be properly tied to either VCC or GND, as specified in the datasheet. Leaving pins floating can cause noise or erratic behavior.

4. Overheating and Thermal Management

Overheating is another issue that can affect the performance and reliability of the AMC1311DWVR. Like many precision components, the AMC1311DWVR is sensitive to excessive temperatures, which can result in device failure or degraded performance.

Possible Causes:

Insufficient ventilation: If the AMC1311DWVR is housed in an enclosure without adequate ventilation, the temperature inside the enclosure may rise, leading to overheating.

High power dissipation: Although the AMC1311DWVR is designed to be energy-efficient, excessive current draw or poor thermal design can lead to heat buildup.

Solution:

Improve airflow: Ensure that the device is placed in an enclosure with proper ventilation. Using heat sinks or fans can help dissipate heat and maintain the device at an optimal operating temperature.

Optimize power consumption: Review the circuit design to ensure that the AMC1311DWVR is not being overdriven or subjected to excessive currents. This can be managed by choosing appropriate resistor values and ensuring that the load does not exceed the recommended specifications.

5. Incompatibility with Logic Levels

In some cases, the AMC1311DWVR may not be compatible with the logic levels of other devices in the system. This can cause the isolator to fail to transmit or receive signals correctly.

Possible Causes:

Mismatched logic levels: If the AMC1311DWVR is designed to operate at 3.3V logic levels but is connected to a 5V system, this can result in voltage level mismatches that prevent the isolator from functioning properly.

Incompatible voltage thresholds: Different logic families have different voltage thresholds for interpreting high and low levels. If the AMC1311DWVR is interfacing with devices that have incompatible voltage thresholds, communication can fail.

Solution:

Ensure compatibility: Check the voltage levels and logic family requirements of the AMC1311DWVR and the devices it interface s with. If necessary, use level-shifting circuits to match the logic levels between different components.

Use the correct version: The AMC1311DWVR comes in different voltage options (e.g., 3.3V and 5V). Ensure that the version you are using is compatible with your system’s voltage levels.

Advanced Troubleshooting and Solutions for AMC1311DWVR

While the above troubleshooting steps address some of the most common issues, advanced users may encounter more complex problems requiring in-depth analysis and specialized solutions. In this section, we will explore some advanced troubleshooting techniques and solutions for users who need a deeper understanding of the AMC1311DWVR’s operation.

6. Unexpected Isolation Behavior

One of the key features of the AMC1311DWVR is its ability to provide galvanic isolation between high-voltage and low-voltage circuits. However, issues related to isolation can occur, particularly when the device behaves unexpectedly under certain conditions.

Possible Causes:

Faulty isolation: If the isolation barrier fails or degrades, the device will no longer function as intended. This could happen due to excessive stress on the isolation layer, exceeding voltage ratings, or poor manufacturing quality.

Insufficient isolation voltage: The AMC1311DWVR is rated for isolation up to 5000V RMS. If this voltage rating is exceeded, the isolator may break down, leading to catastrophic failure.

Solution:

Ensure that the operating voltage does not exceed the maximum isolation voltage specified in the datasheet (5000V RMS). If the isolation barrier is under stress or approaching its breakdown threshold, it may be necessary to replace the component.

Implement safety checks: Design your system with appropriate safety margins and include over-voltage protection to prevent spikes that could damage the isolation.

7. Failure to Initialize or Communicate

In some systems, users may find that the AMC1311DWVR fails to initialize or communicate correctly with the rest of the system. This issue could arise from a variety of sources, including signal issues, incorrect Timing , or improper configuration.

Possible Causes:

Clock ing issues: If the clock signal is not properly generated or synchronized, the AMC1311DWVR may fail to transmit data.

Timing mismatches: Timing mismatches between the isolator and other devices in the system can result in communication failure. The AMC1311DWVR uses precise timing, and any deviation from the expected timing could cause issues.

Solution:

Check clock signals: Ensure that the clock signal is stable and properly routed. Use an oscilloscope to check for clean, noise-free clock edges.

Verify timing requirements: Review the timing diagrams in the datasheet and ensure that the AMC1311DWVR is operating within the specified timing parameters. If necessary, adjust the timing or delay lines in your circuit to match the isolator’s requirements.

8. EMC and EMI Performance Issues

Electromagnetic compatibility (EMC) and electromagnetic interference (EMI) are critical concerns in many high-speed electronic systems. If your application involves high-speed signals or operates in an electrically noisy environment, the AMC1311DWVR may be susceptible to EMI or EMC-related issues.

Possible Causes:

Insufficient shielding: If the device is not adequately shielded from external interference, EMI can impact its performance, leading to errors or signal degradation.

Poor PCB design: Inadequate grounding, routing, or placement of components on the PCB can make the system more susceptible to EMI.

Solution:

Add shielding: Use metal enclosures or EMI shields to protect the AMC1311DWVR from external interference.

Improve PCB design: Use dedicated ground planes, minimize trace lengths, and carefully route high-speed signals to reduce susceptibility to EMI. Additionally, consider using ferrite beads or filters to block high-frequency noise.

9. Component Failure or Degradation

Over time, components can degrade or fail due to prolonged use, environmental conditions, or improper handling. If the AMC1311DWVR starts malfunctioning after a period of operation, it may be due to component wear or environmental factors.

Possible Causes:

Environmental factors: Exposure to extreme temperatures, humidity, or corrosive environments can degrade the performance of the isolator.

Overstress: Overdriving the AMC1311DWVR or subjecting it to excessive voltages or currents can lead to failure.

Solution:

Inspect environmental conditions: Ensure that the AMC1311DWVR is used within its specified temperature range and is protected from humidity or corrosive substances.

Replace degraded components: If the component is visibly damaged or no longer performing as expected, consider replacing it with a new one.

In conclusion, while the AMC1311DWVR is a highly reliable and efficient digital isolator, troubleshooting and resolving issues can sometimes require a systematic approach and attention to detail. By following the solutions and techniques outlined in this guide, users can address common problems and ensure the continued reliability and performance of their AMC1311DWVR-based systems.

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.

Partnering with an electronic components supplier sets your team up for success, ensuring the design, production, and procurement processes are quality and error-free.