MPU-9250 Common troubleshooting and solutions

Understanding the MPU-9250 and Common Issues

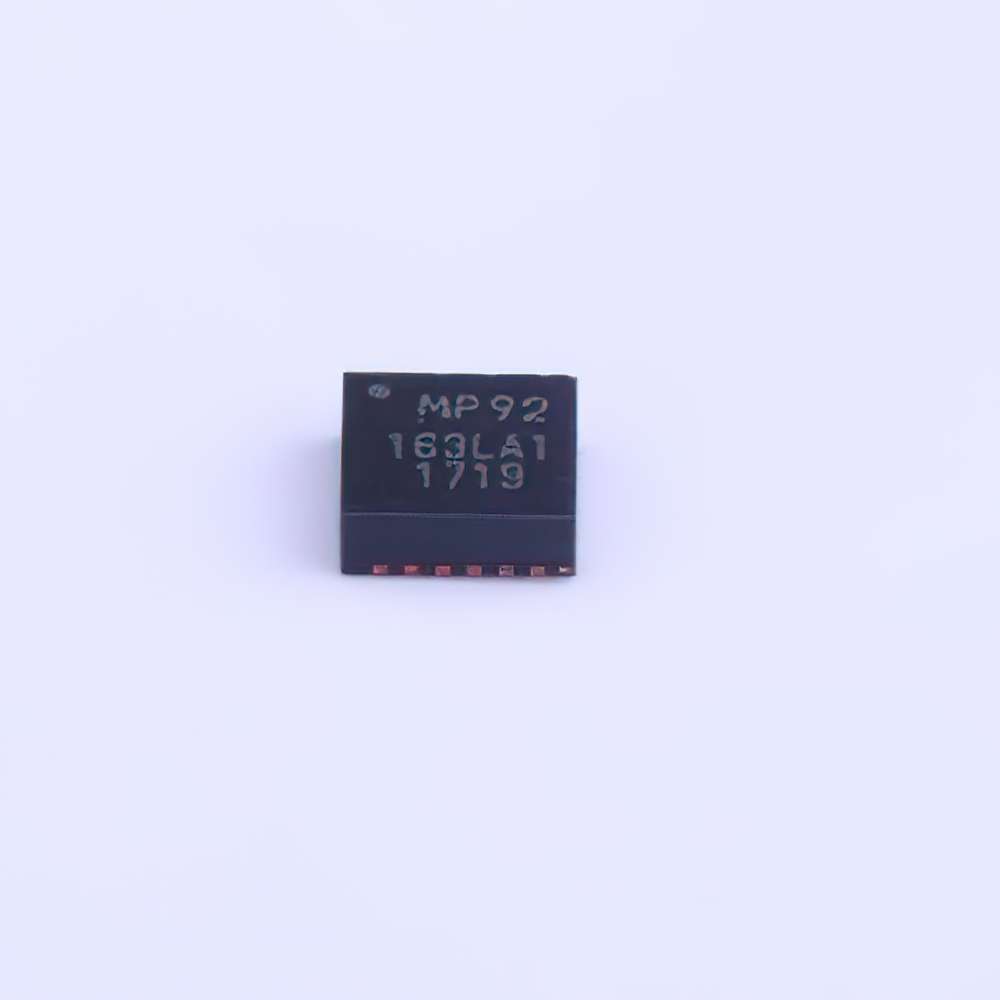

The MPU-9250 is a highly versatile, 9-axis MEMS (Micro-Electromechanical Systems) Sensor , featuring an accelerometer, gyroscope, and magnetometer in one compact unit. It is widely used in applications such as robotics, drones, motion tracking, and wearable devices. However, like any electronic device, it may sometimes face issues that can affect its performance. In this article, we’ll walk through some of the most common problems encountered with the MPU-9250 sensor and offer solutions to help resolve them.

1. Sensor Not Responding or No Data Output

One of the most common problems that users face with the MPU-9250 is when the sensor doesn’t respond, or there’s no data output from the sensor. This could be due to several issues:

Incorrect Wiring or Connections: If you’re using the MPU-9250 on a breadboard or a custom PCB, ensure all the wiring is correct. The sensor communicates via I2C or SPI, so check the connection of the SDA, SCL (I2C), or MISO, MOSI, SCK, and CS pins (SPI). Poor connections or loose wires can prevent the sensor from functioning properly.

Power Supply Issues: The MPU-9250 requires a stable voltage supply of 3.3V to 5V. If the supply voltage fluctuates or is too low, the sensor may fail to operate. Verify that your power source is adequate and stable.

Faulty I2C Communication : The MPU-9250 uses I2C to send data to the microcontroller. If there’s a problem with I2C communication, like incorrect addressing or SDA/SCL timing issues, the sensor may not provide data. You can check this by using an I2C scanner program to ensure that the sensor is properly detected on the bus.

2. Inaccurate or Unreliable Data

If you are receiving data from the MPU-9250 but it seems inaccurate or unreliable, there could be several causes to investigate:

Uncalibrated Sensor: The accelerometer, gyroscope, and magnetometer in the MPU-9250 need calibration for accurate measurements. If you haven’t calibrated the sensor, or if it was calibrated improperly, the data may be skewed. Most problems with inaccurate readings can be resolved through proper calibration procedures.

Magnetic Interference: The magnetometer in the MPU-9250 is sensitive to magnetic fields, and interference from nearby electronics, motors, or metal objects can cause distortion in the magnetic field readings. Make sure the sensor is positioned away from potential sources of magnetic interference. You can also calibrate the magnetometer to minimize errors caused by surrounding fields.

Temperature Drift: The performance of MEMS Sensors , including those in the MPU-9250, can drift with temperature changes. If you notice that the sensor readings fluctuate significantly with temperature, it could be due to a lack of temperature compensation. Some sensor libraries include algorithms for temperature compensation, so ensure that you are using the latest version of the library that accounts for this.

3. Sensor Freezing or Lockups

Occasionally, the MPU-9250 may freeze or lock up, especially when it is being used in complex systems or when the data rate is set too high. This can be frustrating, especially in real-time applications like robotics or drones.

Overloaded I2C Bus: When multiple devices share the I2C bus, the communication speed may become a bottleneck. This can cause the MPU-9250 to freeze or fail to respond. If you're using multiple sensors on the same bus, consider optimizing the bus usage by reducing the frequency of data reads or using SPI for faster communication.

Incorrect Firmware or Software: Ensure that the firmware running on your microcontroller is correctly set up to communicate with the MPU-9250. Incorrect timing, register settings, or faulty logic in the code can lead to the sensor freezing. Check the sensor’s datasheet and cross-check your code to ensure the sensor is properly initialized.

Power Interruptions: Unstable power or sudden interruptions can cause the MPU-9250 to freeze. Ensure that your power supply is stable, and consider adding capacitor s or using a regulated power source to prevent power dips that could cause instability.

Advanced Troubleshooting and Solutions

If you've addressed the basic issues outlined above but are still facing difficulties with the MPU-9250, here are some advanced troubleshooting steps and solutions.

4. Accelerometer and Gyroscope Not Functioning

The accelerometer and gyroscope in the MPU-9250 are critical for motion sensing, and when either of these components fails, it can significantly impact performance. Here are some possible causes:

Faulty Initialization: Both the accelerometer and gyroscope require proper initialization to work correctly. If the sensor is not initialized correctly in the code, it might not start collecting data. Double-check the initialization sequence and ensure that you’re setting the correct parameters, such as the accelerometer’s full-scale range or the gyroscope’s sensitivity.

Disabled Sensors: The MPU-9250 allows you to enable or disable the accelerometer and gyroscope independently. If you accidentally disable one of these sensors through software, the corresponding data will not be available. Verify that both sensors are enabled by checking their respective control registers in the sensor’s configuration.

Hardware Failure: In rare cases, the hardware of the accelerometer or gyroscope might be damaged. If you’ve ruled out all software and configuration issues, you may want to consider replacing the MPU-9250 if it’s underperforming or not outputting data from either of these sensors.

5. Magnetometer Issues

The magnetometer is responsible for measuring the magnetic field and is used for heading and orientation detection. If your magnetometer readings are incorrect or inconsistent, here’s what you can do:

Magnetic Interference: As mentioned earlier, magnetic fields from surrounding electronics can distort the magnetometer readings. Check if the MPU-9250 is located near devices like motors, transformers, or even large metallic objects, all of which can interfere with the sensor. Moving the sensor away from these sources can help.

Magnetometer Calibration: If the magnetometer readings are not accurate, it’s essential to perform a calibration. This process involves moving the sensor in a specific pattern (typically a figure-eight motion) to create a 3D mapping of the magnetic field. Calibration libraries and algorithms are available online, and following the correct procedure can significantly improve the accuracy of the magnetometer readings.

Faulty Magnetometer: In some cases, the magnetometer may be faulty, resulting in no data output or highly inaccurate readings. If you suspect a hardware fault, testing the sensor with known good hardware or replacing it may be necessary.

6. Sensor Overload and Data Saturation

In high-speed applications, such as robotics or motion tracking, it’s possible to overload the MPU-9250 with too much data or too high a sampling rate. This can cause the sensor to drop data or become unresponsive.

Adjust the Sampling Rate: The MPU-9250 has configurable sampling rates for both the accelerometer and the gyroscope. If you’re pushing the sensor too hard by requesting data too frequently, you might saturate the communication bus or the sensor’s internal buffers. Try reducing the sampling rate to a more manageable level (e.g., 100 Hz for the accelerometer or 200 Hz for the gyroscope).

Use FIFO Buffer: The MPU-9250 has a built-in FIFO (First-In-First-Out) buffer that can store multiple data samples before they are read by the microcontroller. Enabling the FIFO buffer can help you manage high data throughput without overloading the system.

7. Updating the Firmware and Software Libraries

Sometimes, issues with the MPU-9250 stem from outdated software or firmware. Ensure that you’re using the latest sensor libraries and that your microcontroller firmware is up to date.

Library Updates: The development community frequently updates sensor libraries to fix bugs and improve performance. If you’re using an older version of the library, check the manufacturer’s website or popular GitHub repositories for the latest releases. These updates may include important fixes related to stability, data accuracy, and compatibility.

Firmware Upgrades: If you’re using a development board with embedded firmware, check for firmware updates from the manufacturer. Newer firmware versions may include improvements that fix specific issues with sensor communication, power management, and performance.

Conclusion

The MPU-9250 is a powerful and versatile sensor that can be used for a wide range of applications, but like any complex piece of hardware, it can face challenges during operation. By following the troubleshooting steps outlined in this article, you can identify and resolve common issues that may arise when using the sensor. Whether the problem lies in wiring, calibration, software, or hardware, this guide provides the necessary steps to get your MPU-9250 back on track for reliable performance.

Partnering with an electronic components supplier sets your team up for success, ensuring the design, production, and procurement processes are quality and error-free.